Training Course on Process Plant Optimization Technology and Continual Improvement

Training Course on Process Plant Optimization Technology and Continual Improvement equips professionals with the essential knowledge and practical skills to enhance the efficiency, reliability, and profitability of process plants.

Course Overview

Training Course on Process Plant Optimization Technology and Continual Improvement

Introduction

Training Course on Process Plant Optimization Technology and Continual Improvement equips professionals with the essential knowledge and practical skills to enhance the efficiency, reliability, and profitability of process plants. Through a comprehensive curriculum, participants will learn to identify operational bottlenecks, implement optimization strategies, and foster a culture of continuous improvement. Strong emphasis will be placed on leveraging technology and data-driven methodologies to achieve sustainable operational excellence and significant cost reduction.

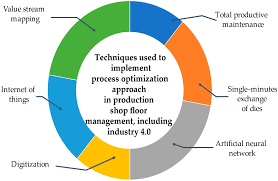

The program delves into the core principles of process optimization, covering equipment reliability, energy management, and the application of continual improvement methodologies. Participants will gain expertise in debottlenecking, revamping, and the integration of advanced technologies to maximize plant performance. By focusing on operational efficiency and the elimination of waste, this course empowers attendees to drive significant improvements in their organizations, contributing directly to enhanced productivity and a stronger competitive edge through sustainable optimization.

Course Duration

10 days

Course Objectives

- Understand the fundamental principles of process plant optimization.

- Identify and analyze operational bottlenecks affecting plant performance.

- Develop and implement effective debottlenecking strategies.

- Learn methodologies for enhancing equipment reliability and availability.

- Apply techniques for optimizing energy consumption and management.

- Master the tools and principles of continual improvement methodologies.

- Evaluate and implement advanced control systems for process enhancement.

- Utilize data analysis for informed decision-making in plant optimization.

- Develop strategies for revamping aging systems and integrating new technologies.

- Understand the importance of maintenance optimization for plant efficiency.

- Apply risk-based inspection and fitness-for-service analysis.

- Learn to measure and sustain process improvements using KPIs.

- Foster a culture of operational excellence and continuous improvement within the organization.

Organizational Benefits

- Reduced operational costs through optimized processes and resource utilization.

- Enhanced production efficiency and increased throughput.

- Improved plant reliability and reduced downtime.

- Better product quality and consistency.

- More efficient energy consumption and lower utility bills.

- Increased profitability and a stronger competitive position.

- A workforce equipped with the skills to drive continuous improvement.

- Improved safety and environmental performance.

- Better decision-making based on data-driven insights.

- Enhanced ability to adapt to changing market demands and regulations.

Target Audience

- Process Engineers

- Plant Operators

- Maintenance and Reliability Professionals

- Production Managers

- Operations Managers

- Manufacturing Engineers

- Project Managers involved in plant revamping

- Technical and Operational Managers in process industries

Course Outline

Module 1: Fundamentals of Process Plant Optimization

- Introduction to Plant Optimization: Objectives and Benefits

- Key Performance Indicators (KPIs) for evaluating plant efficiency

- Overview of Optimization Technologies for Process Plants

- Constraints in Optimization: Production, Operation, Economy, Environment

- Case Study: Identifying potential optimization areas in a chemical plant.

Module 2: Process Mapping and Analysis

- Techniques for mapping manufacturing processes

- Identifying bottlenecks and inefficiencies in process flows

- Value Stream Mapping (VSM) for process improvement

- Data collection and analysis for process understanding

- Case Study: Analyzing a bottleneck in a food processing line.

Module 3: Lean Tools for Process Optimization

- Introduction to Lean Manufacturing principles

- Application of 5S methodology for workplace organization

- Waste identification and elimination (Muda, Mura, Muri)

- Just-in-Time (JIT) and its relevance to process optimization

- Case Study: Implementing 5S in a packaging facility.

Module 4: Improving Process Flow and Layout

- Principles of efficient plant layout design

- Strategies for improving material flow and reducing movement

- Line balancing techniques for optimizing production flow

- Ergonomics in process design for enhanced efficiency

- Case Study: Redesigning a workshop layout for better workflow.

Module 5: Measuring and Sustaining Process Improvements

- Setting clear and measurable objectives for improvement projects

- Tools for tracking and monitoring process performance

- Statistical Process Control (SPC) for quality monitoring

- Developing control plans to sustain improvements

- Case Study: Using SPC to monitor and control product quality.

Module 6: Equipment Reliability and Maintenance Optimization

- Understanding equipment failure modes and their impact

- Preventive and Predictive Maintenance strategies

- Root Cause Analysis (RCA) for identifying failure causes

- Reliability-Centered Maintenance (RCM) principles

- Case Study: Implementing a predictive maintenance program for critical pumps.

Module 7: Energy Management and Efficiency

- Identifying major energy consumers in process plants

- Strategies for reducing energy consumption and waste

- Energy auditing and benchmarking techniques

- Implementing energy-efficient technologies and practices

- Case Study: Reducing steam consumption in a refinery.

Module 8: Advanced Control and Automation

- Overview of advanced process control (APC) systems

- The role of automation in process optimization

- Data integration and analytics for control improvement

- Model Predictive Control (MPC) concepts

- Case Study: Implementing APC in a distillation column.

Module 9: Debottlenecking and Capacity Creep

- Identifying constraints and bottlenecks limiting plant capacity

- Techniques for debottlenecking without major capital investment

- Understanding and managing capacity creep

- Economic evaluation of debottlenecking projects

- Case Study: Debottlenecking a heat exchanger network.

Module 10: Revamping and Technology Integration

- Strategies for revamping aging process plants

- Evaluating and selecting new technologies for plant upgrades

- Managing the challenges of technology integration

- Lifecycle cost analysis for revamping projects

- Case Study: Integrating a new catalyst technology in a reactor.

Module 11: Risk-Based Inspection and Fitness for Service

- Principles of Risk-Based Inspection (RBI)

- Fitness-For-Service (FFS) assessment methodologies

- Applying RBI and FFS to optimize inspection and maintenance

- Remaining life assessment of critical equipment

- Case Study: Using RBI to prioritize inspection of pressure vessels.

Module 12: Environmental Optimization and Sustainability

- Minimizing environmental impact of process plant operations

- Waste reduction and management strategies

- Water conservation and treatment optimization

- Emissions control and monitoring

- Case Study: Implementing a wastewater treatment optimization project.

Module 13: Change Management and Continuous Improvement Culture

- Principles of effective change management

- Engaging employees in continuous improvement initiatives

- Implementing Kaizen events and improvement teams

- Recognizing and rewarding improvement efforts

- Case Study: Fostering a continuous improvement culture in a manufacturing organization.

Module 14: Data Analytics for Process Optimization

- Introduction to data analytics tools and techniques

- Using process data for performance monitoring and diagnosis

- Predictive analytics for proactive decision-making

- Data visualization for effective communication of insights

- Case Study: Using data analytics to predict equipment failures.

Module 15: Project Management for Optimization Initiatives

- Planning and executing process optimization projects

- Defining project scope, timelines, and resources

- Risk management in optimization projects

- Stakeholder management and communication

- Case Study: Managing a plant-wide energy optimization project.

Training Methodology

This training course will employ a blended learning approach, incorporating:

- Interactive lectures with real-world examples and case studies.

- Group discussions and experience sharing among participants.

- Practical exercises and simulations to apply learned concepts.

- Case study analysis to understand industry best practices and challenges.

- Q&A sessions to address specific queries and enhance understanding.

Register as a group from 3 participants for a Discount

Send us an email: info@datastatresearch.org or call +254724527104

Certification

Upon successful completion of this training, participants will be issued with a globally- recognized certificate.

Tailor-Made Course

We also offer tailor-made courses based on your needs.

Key Notes

a. The participant must be conversant with English.

b. Upon completion of training the participant will be issued with an Authorized Training Certificate

c. Course duration is flexible and the contents can be modified to fit any number of days.

d. The course fee includes facilitation training materials, 2 coffee breaks, buffet lunch and A Certificate upon successful completion of Training.

e. One-year post-training support Consultation and Coaching provided after the course.

f. Payment should be done at least a week before commence of the training, to DATASTAT CONSULTANCY LTD account, as indicated in the invoice so as to enable us prepare better for you.