Training Course on Predictive Maintenance and Health Monitoring (PHM) in Aviation

Training Course on Predictive Maintenance and Health Monitoring (PHM) in Aviation to equip aviation professionals, engineers, and maintenance teams with practical knowledge and skills to implement PHM strategies that reduce downtime, optimize maintenance schedules, and enhance flight safety.

Course Overview

Training Course on Predictive Maintenance and Health Monitoring (PHM) in Aviation

Introduction

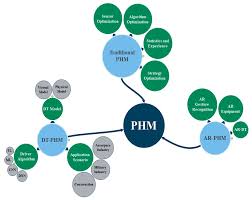

Predictive Maintenance and Health Monitoring (PHM) in Aviation is a cutting-edge discipline revolutionizing aircraft maintenance by leveraging advanced data analytics, IoT sensors, and AI technologies. Training Course on Predictive Maintenance and Health Monitoring (PHM) in Aviation to equip aviation professionals, engineers, and maintenance teams with practical knowledge and skills to implement PHM strategies that reduce downtime, optimize maintenance schedules, and enhance flight safety. As the aviation industry moves towards smarter, data-driven operations, mastering PHM is essential for staying competitive and compliant with global aviation standards.

This training provides a deep dive into the latest predictive maintenance tools, real-time health monitoring techniques, and actionable insights through case studies and hands-on methodologies. Participants will gain expertise in using condition-based monitoring, failure prediction models, and advanced diagnostics to minimize unexpected failures and extend aircraft lifecycle. Whether you’re a maintenance engineer, fleet manager, or aviation safety specialist, this course empowers you to harness predictive technologies and transform maintenance operations for the future of aviation.

Course Duration

5 days

Course Objectives

- Understand the fundamentals and importance of Predictive Maintenance in Aviation.

- Master the use of IoT sensors and real-time data acquisition for health monitoring.

- Analyze aircraft system data for early fault detection and diagnostics.

- Implement AI and machine learning algorithms for predictive analytics.

- Develop condition-based maintenance strategies to optimize resources.

- Apply risk management and reliability engineering principles in PHM.

- Interpret sensor data for engine, avionics, and structural health monitoring.

- Integrate PHM systems with existing Aircraft Maintenance Management Systems (AMMS).

- Use cloud computing and big data analytics for aviation maintenance insights.

- Evaluate cost-benefit analysis and ROI of predictive maintenance programs.

- Navigate regulatory and compliance standards related to PHM in aviation.

- Enhance safety protocols through continuous health monitoring.

- Build a roadmap for implementing PHM in commercial and military aviation fleets.

Organizational Benefits

- Significant reduction in unplanned aircraft downtime and operational disruptions.

- Increased aircraft availability and utilization leading to higher ROI.

- Proactive detection and resolution of potential failures, enhancing safety.

- Optimized maintenance scheduling reducing labor and material costs.

- Extended lifespan of critical aircraft components through timely interventions.

- Compliance with international aviation safety regulations and standards.

- Improved decision-making with real-time, data-driven maintenance insights.

- Enhanced competitiveness through adoption of next-gen predictive technologies.

Target Audience

- Aircraft Maintenance Engineers

- Aviation Safety Officers

- Fleet Managers

- Aerospace Engineers

- Aviation Maintenance Technicians

- Airline Operations Managers

- Aviation Regulatory Compliance Specialists

- Maintenance Planning and Reliability Analysts

Course Outline

Module 1: Introduction to Predictive Maintenance and PHM

- Fundamentals and evolution of PHM in aviation

- Benefits over traditional maintenance approaches

- Overview of aviation maintenance standards and regulations

- Key components of a PHM system

- Case Study: Successful PHM implementation in a commercial airline

Module 2: Sensors and Data Acquisition in Aviation

- Types of IoT sensors used in aircraft monitoring

- Data collection methods and protocols

- Sensor placement and integration challenges

- Real-time data transmission and processing

- Case Study: Engine vibration monitoring for early fault detection

Module 3: Data Analytics and Machine Learning for PHM

- Basics of data analytics and predictive modeling

- Machine learning algorithms for fault prediction

- Data cleaning, feature extraction, and model training

- Predictive analytics software and tools

- Case Study: AI-based engine health prognostics

Module 4: Condition-Based and Risk-Based Maintenance

- Difference between condition-based and risk-based strategies

- Developing maintenance triggers from sensor data

- Risk assessment frameworks and reliability engineering

- Prioritizing maintenance actions for safety and cost efficiency

- Case Study: Risk-based maintenance in helicopter fleets

Module 5: Integration with Aircraft Maintenance Management Systems

- Overview of AMMS and its components

- Integrating PHM data with AMMS workflows

- Challenges in system interoperability

- Workflow automation and alert management

- Case Study: Seamless PHM-AMMS integration in cargo aircraft

Module 6: Regulatory Compliance and Safety Standards

- Overview of FAA, EASA, and ICAO guidelines for PHM

- Documentation and audit readiness

- Safety management systems and PHM’s role

- Handling data security and privacy concerns

- Case Study: Regulatory approval process for PHM in military aircraft

Module 7: Cost-Benefit Analysis and ROI of PHM

- Calculating cost savings from predictive maintenance

- Financial modeling for PHM investments

- Metrics to track PHM success

- Case Study: ROI analysis of PHM program in a regional airline

Module 8: Future Trends and Innovations in Aviation PHM

- Emerging technologies: AI, edge computing, and digital twins

- Predictive maintenance for electric and hybrid aircraft

- Role of blockchain in maintenance records

- Preparing for Industry 4.0 in aviation maintenance

- Case Study: Digital twin implementation for fleet health monitoring

Training Methodology

- Interactive lectures and multimedia presentations

- Hands-on workshops with sensor data and analytic tools

- Real-world case study analysis and group discussions

- Simulation exercises for fault detection and troubleshooting

- Assessments through quizzes, projects, and practical demonstrations

Register as a group from 3 participants for a Discount

Send us an email: info@datastatresearch.org or call +254724527104

Certification

Upon successful completion of this training, participants will be issued with a globally- recognized certificate.

Tailor-Made Course

We also offer tailor-made courses based on your needs.

Key Notes

a. The participant must be conversant with English.

b. Upon completion of training the participant will be issued with an Authorized Training Certificate

c. Course duration is flexible and the contents can be modified to fit any number of days.

d. The course fee includes facilitation training materials, 2 coffee breaks, buffet lunch and A Certificate upon successful completion of Training.

e. One-year post-training support Consultation and Coaching provided after the course.

f. Payment should be done at least a week before commence of the training, to DATASTAT CONSULTANCY LTD account, as indicated in the invoice so as to enable us prepare better for you.