Training course on Digital Fabrication Techniques in Construction

Training Course on Digital Fabrication Techniques in Construction is meticulously designed to provide participants with the practical application of cutting-edge digital fabrication methodologies

Course Overview

Training Course on Digital Fabrication Techniques in Construction

Introduction

The construction industry has long grappled with persistent challenges, including low productivity rates, significant waste generation, heavy reliance on manual labor, and inherent difficulties in achieving complex geometries and mass customization. Traditional on-site construction methods are often fragmented, time-consuming, and prone to quality variations, thereby impeding innovation and overall efficiency. In this evolving landscape, Digital Fabrication Techniques—encompassing advanced technologies such as 3D printing, robotic assembly, and Computer Numerical Control (CNC) machining—offer a truly transformative solution.3 These methods enable the automated, precise, and highly efficient production of building components and entire structures directly from digital models, fundamentally revolutionizing how buildings are conceived, manufactured, and assembled.

Training Course on Digital Fabrication Techniques in Construction is meticulously designed to provide participants with the practical application of cutting-edge digital fabrication methodologies specifically tailored for the construction sector. The curriculum will encompass a deep understanding of the principles behind various additive manufacturing (3D printing) technologies applicable to concrete, polymers, and metals; a thorough exploration of robotic systems for automated tasks like bricklaying, welding, and component assembly; and mastery of CNC machining for the precise cutting and shaping of diverse materials. Participants will also delve into integrating these techniques with Building Information Modeling (BIM) workflows, considering material properties for digital fabrication, implementing robust quality control measures, and planning for scalable deployment. Through a balanced blend of essential theoretical foundations, extensive hands-on exercises, software demonstrations, and practical project-based learning, this course will comprehensively prepare attendees to design for, implement, and effectively manage digitally fabricated elements, fostering more sustainable, efficient, and innovative construction practices.

Course Objectives

Upon completion of this course, participants will be able to:

- Analyze the fundamental concepts of Digital Fabrication and its transformative impact on the construction industry.

- Comprehend the principles and operational characteristics of various Additive Manufacturing (3D Printing) technologies for construction materials.

- Master techniques for designing and preparing digital models for fabrication using Building Information Modeling (BIM) and specialized software.

- Develop expertise in utilizing robotic systems for automated construction tasks, including assembly, welding, and material handling.

- Formulate strategies for applying Computer Numerical Control (CNC) machining for precise cutting and shaping of building components.

- Understand the critical role of material properties and performance in successful digital fabrication processes in construction.

- Implement robust approaches to quality control, error detection, and process optimization in digitally fabricated construction.

- Explore key strategies for integrating digital fabrication workflows with site logistics and traditional construction practices.

- Apply methodologies for assessing the economic, environmental, and design benefits of digital fabrication in projects.

- Understand the importance of safety protocols, automation ethics, and skilled labor requirements in digital fabrication environments.

- Develop preliminary skills in utilizing software for robotic programming, 3D printing slicing, and CNC path generation.

- Design a conceptual digital fabrication strategy for a specific construction component or project scenario.

- Examine global best practices and future trends in digital construction, modularization, and AI-driven fabrication.

Target Audience

This course is ideal for professionals in architecture, engineering, and construction looking to embrace advanced manufacturing:

- Architects & Designers: Seeking to leverage digital fabrication for complex geometries and new aesthetics.

- Civil & Structural Engineers: Interested in structural applications and material innovation through digital fabrication.

- Construction Managers: Aiming to improve productivity, reduce waste, and enhance quality control.5

- BIM Specialists: Focusing on integrating design and fabrication workflows.

- Manufacturing & Fabrication Professionals: Transitioning skills to the construction sector.

- Researchers & Academics: Exploring advanced robotics, automation, and material science in construction.

- Product Developers in Construction: Designing prefabricated and customized building components.

- Policy Makers & Innovators: Guiding the adoption of advanced manufacturing in the built environment.

Course Duration: 5 Days

Course Modules

- Module 1: Introduction to Digital Fabrication in Construction

- Define digital fabrication and its historical evolution in manufacturing and construction.

- Discuss the limitations of traditional construction and the drivers for automation.

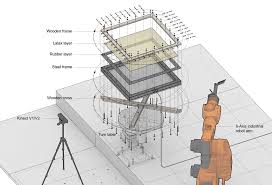

- Understand the core technologies: 3D printing, robotics, CNC machining.6

- Explore the benefits: precision, speed, customization, waste reduction, safety.

- Identify key applications and early examples of digital fabrication in construction.

- Module 2: Additive Manufacturing (3D Printing) for Construction

- Comprehend the principles of various 3D printing technologies (e.g., concrete extrusion, powder binding, metal printing).

- Learn about suitable materials for construction 3D printing (cementitious, polymers, composites).

- Master techniques for preparing digital models for 3D printing (slicing, path generation).

- Discuss challenges: scalability, structural integrity, regulatory hurdles.

- Apply knowledge to design a basic printable concrete element.

- Module 3: Robotics in Construction and Automated Assembly

- Develop expertise in understanding different types of industrial robots (e.g., articulated arms, gantry robots, mobile robots).

- Learn about applications of robotics: automated bricklaying, welding, prefabrication, demolition.

- Master techniques for basic robotic programming and simulation for construction tasks.

- Discuss human-robot collaboration and safety considerations on construction sites.

- Apply robotic principles to conceptualize an automated assembly process.

- Module 4: Subtractive Fabrication (CNC Machining) and Hybrid Processes

- Formulate strategies for applying Computer Numerical Control (CNC) machining for precise cutting, routing, and milling.

- Understand the principles of CNC operations for materials like timber, steel, and composites.

- Explore techniques for generating toolpaths from digital models for efficient material removal.

- Discuss hybrid fabrication approaches combining additive, subtractive, and robotic methods.

- Apply CNC concepts to design a precisely cut timber joinery component.

- Module 5: Design for Digital Fabrication (DfDF) and BIM Integration

- Understand the critical role of Design for Digital Fabrication (DfDF) principles.

- Implement robust approaches to optimizing designs for manufacturability and assembly efficiency.

- Explore techniques for leveraging Building Information Modeling (BIM) for seamless data flow from design to fabrication.

- Discuss the use of parametric design and computational design tools (e.g., Grasshopper, Dynamo) for complex geometries.

- Examine case studies demonstrating effective DfDF and BIM integration.

- Module 6: Materials Science and Quality Control in Digital Fabrication

- Apply methodologies for understanding material behavior and performance specifically for digital fabrication processes.

- Master techniques for ensuring material consistency and quality control in automated production.

- Understand the challenges of material development for novel fabrication techniques.

- Discuss methods for non-destructive testing (NDT) and in-situ monitoring of fabricated components.

- Explore strategies for minimizing waste and promoting sustainability in digital fabrication.

- Module 7: Implementation and Project Management of Digital Fabrication

- Explore key strategies for planning and managing digital fabrication workflows in large-scale projects.

- Learn about integrating off-site digital fabrication with on-site construction logistics.

- Discuss supply chain management and procurement for digitally fabricated components.

- Understand the economic implications: cost savings, upfront investment, ROI.

- Examine methods for project risk assessment and mitigation in digitally fabricated construction.

- Module 8: Future Trends and Disruption in Construction

- Examine global best practices and innovative applications of digital fabrication in pioneering projects.

- Develop preliminary skills in assessing emerging technologies: intelligent automation, AI-driven design, bio-fabrication.

- Discuss the convergence of digital fabrication with modular construction, prefabrication, and digital twins.

- Explore future trends: adaptive construction, self-assembling structures, personalized architecture.

- Design a strategic roadmap for adopting digital fabrication technologies in an AEC firm.

Training Methodology

- Interactive Workshops: Facilitated discussions, group exercises, and problem-solving activities.

- Case Studies: Real-world examples to illustrate successful community-based surveillance practices.

- Role-Playing and Simulations: Practice engaging communities in surveillance activities.

- Expert Presentations: Insights from experienced public health professionals and community leaders.

- Group Projects: Collaborative development of community surveillance plans.

- Action Planning: Development of personalized action plans for implementing community-based surveillance.

- Digital Tools and Resources: Utilization of online platforms for collaboration and learning.

- Peer-to-Peer Learning: Sharing experiences and insights on community engagement.

- Post-Training Support: Access to online forums, mentorship, and continued learning resources.

Register as a group from 3 participants for a Discount

Send us an email: info@datastatresearch.org or call +254724527104

Certification

Upon successful completion of this training, participants will be issued with a globally recognized certificate.

Tailor-Made Course

We also offer tailor-made courses based on your needs.

Key Notes

- Participants must be conversant in English.

- Upon completion of training, participants will receive an Authorized Training Certificate.

- The course duration is flexible and can be modified to fit any number of days.

- Course fee includes facilitation, training materials, 2 coffee breaks, buffet lunch, and a Certificate upon successful completion.

- One-year post-training support, consultation, and coaching provided after the course.

- Payment should be made at least a week before the training commencement to DATASTAT CONSULTANCY LTD account, as indicated in the invoice, to enable better preparation.