Big Data Analytics for Predictive Maintenance Strategies Training Course

Big Data Analytics for Predictive Maintenance Strategies Training Course provides a comprehensive guide to leveraging big data analytics and machine learning for developing and implementing predictive maintenance strategies

Course Overview

Big Data Analytics for Predictive Maintenance Strategies Training Course

Introduction

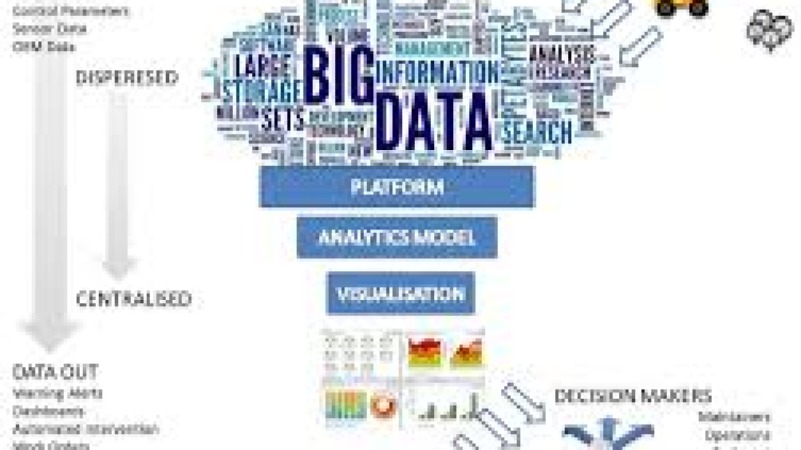

Big Data Analytics for Predictive Maintenance Strategies Training Course provides a comprehensive guide to leveraging big data analytics and machine learning for developing and implementing predictive maintenance strategies. Organizations are under increasing pressure to optimize operational efficiency, minimize costs, and ensure asset reliability. Traditional maintenance approaches often lead to unplanned downtime and high expenses. By harnessing the power of data from industrial IoT sensors, enterprise systems, and maintenance logs, this training empowers professionals to transition from reactive or preventive maintenance to a proactive, data-driven approach.

The course focuses on the practical application of data science techniques to real-world industrial challenges. Participants will learn how to build predictive models that forecast equipment failures, optimize maintenance schedules, and improve asset performance. Through hands-on exercises and case studies, you'll gain the skills to collect, clean, and analyze complex industrial data, leading to significant improvements in asset uptime and overall productivity. This is a must-have skill set for anyone looking to drive digital transformation and secure a competitive advantage in today's Industry 4.0 landscape.

Course Duration

5 days

Course Objectives

By the end of this training, you will be able to:

- Master the fundamentals of predictive maintenance and its role in Industry 4.0.

- Architect a robust big data infrastructure for industrial IoT and operational data.

- Perform advanced data cleaning and feature engineering on sensor data and time-series data.

- Develop and deploy machine learning models for failure prediction and remaining useful life (RUL) estimation.

- Interpret model results and translate them into actionable maintenance decisions.

- Integrate predictive analytics insights with existing Computerized Maintenance Management Systems (CMMS).

- Calculate and demonstrate the return on investment (ROI) of predictive maintenance programs.

- Implement condition monitoring techniques using vibration, thermal, and oil analysis.

- Build a proactive maintenance culture within your organization.

- Analyze data from various sources including SCADA, historians, and enterprise resource planning (ERP) systems.

- Apply root cause failure analysis (RCFA) to improve model accuracy and reliability.

- Optimize maintenance schedules to minimize downtime and maximize asset lifespan.

- Utilize data visualization tools to communicate insights effectively to stakeholders.

Organizational Benefits

- Dramatically decrease maintenance costs by eliminating unnecessary routine maintenance and avoiding catastrophic equipment failures.

- Boost operational efficiency and productivity by minimizing unplanned downtime and optimizing asset availability.

- Improve workplace safety by predicting and preventing equipment malfunctions that could lead to accidents.

- Proactively addressing issues extends the lifespan of critical machinery and infrastructure.

- Transition from reactive to proactive maintenance, enabling smarter, more informed strategic planning.

- Stay ahead of the competition by leveraging cutting-edge technology and data science for operational excellence.

- Achieve a significant return on investment through optimized maintenance strategies and improved resource allocation.

Target Audience

- Maintenance and Reliability Managers

- Plant Operations and Production Managers

- Data Scientists and Data Analysts

- Industrial Engineers and Technicians

- Asset Management Professionals

- IT and IoT Solution Architects

- Business Analysts

- Senior Management overseeing production and operations

Course Outline

Module 1: Introduction to Predictive Maintenance & Big Data

- Understanding the evolution from reactive to predictive maintenance.

- The role of Big Data, IoT, and AI in modern maintenance.

- Key concepts: Condition Monitoring, RUL, and Failure Modes.

- Frameworks for predictive maintenance strategy development.

- Case Study: A major airline uses sensor data from aircraft engines to predict component failures, saving millions in maintenance costs and reducing flight delays.

Module 2: Data Acquisition and Infrastructure

- Identifying and collecting data from various industrial sources

- Building a scalable data pipeline and data lake architecture.

- Data cleaning, normalization, and feature extraction for maintenance data.

- Handling diverse data types: time-series, structured, and unstructured.

- Case Study: A wind farm operator collects data from thousands of turbines to monitor blade vibrations and gear oil temperature, enabling them to schedule maintenance before major component failures.

Module 3: Foundational Predictive Analytics

- Introduction to key data science libraries (Python, R, Pandas, NumPy).

- Exploratory Data Analysis (EDA) to uncover patterns in maintenance data.

- Statistical analysis for identifying correlations and anomalies.

- Introduction to machine learning algorithms for classification and regression.

- Case Study: A manufacturing company uses statistical models on vibration data from assembly line robots to detect early signs of bearing wear.

Module 4: Machine Learning for Failure Prediction

- Building classification models (e.g., Logistic Regression, Random Forest) to predict component failure.

- Developing time-series forecasting models to predict equipment degradation.

- Advanced techniques for handling imbalanced datasets common in maintenance.

- Model evaluation and validation using metrics like precision, recall, and F1-score.

- Case Study: A railway company builds a model to predict rail track faults using data from trackside sensors, reducing derailment risks.

Module 5: Remaining Useful Life (RUL) Estimation

- The concept of prognostics and RUL.

- Using regression models to estimate the remaining lifespan of an asset.

- Implementing survival analysis techniques.

- Evaluating and refining RUL models for accuracy.

- Case Study: An oil and gas company estimates the RUL of offshore drilling equipment, allowing them to schedule replacement during planned shutdowns, avoiding costly emergency repairs.

Module 6: Implementation and Integration

- Developing a pilot project and scaling a predictive maintenance program.

- Integrating predictive models with existing CMMS and EAM systems.

- Creating dashboards and data visualizations for real-time monitoring.

- Building a cross-functional team of data scientists and maintenance engineers.

- Case Study: A utility company integrates a predictive model for transformer health with their asset management system, automating maintenance work orders.

Module 7: Condition Monitoring Technologies

- Vibration analysis to detect mechanical faults.

- Thermal imaging for identifying overheating components.

- Acoustic monitoring for detecting leaks and electrical discharge.

- Oil analysis for monitoring wear particles and lubricant condition.

- Case Study: A mining company uses a combination of vibration sensors and thermal cameras on conveyor belts to predict and prevent roller bearing failures.

Module 8: Advanced Topics & Future Trends

- Introduction to Deep Learning and its applications in predictive maintenance.

- The role of Digital Twins in asset management.

- Understanding and mitigating data security and privacy risks.

- Exploring the future of predictive maintenance with Edge Computing and Generative AI.

- Case Study: A smart factory leverages a digital twin to simulate the performance of its robotic arms and predict maintenance needs, further optimizing production.

Training Methodology

This course employs an interactive, hands-on methodology to ensure practical skill acquisition. The training includes a mix of:

- Instructor-led lectures and expert presentations.

- Practical exercises and lab sessions using real-world datasets.

- Group discussions and collaborative problem-solving.

- Case studies and scenario-based learning.

- Q&A sessions and one-on-one expert guidance.

Register as a group from 3 participants for a Discount

Send us an email: [email protected] or call +254724527104

Certification

Upon successful completion of this training, participants will be issued with a globally- recognized certificate.

Tailor-Made Course

We also offer tailor-made courses based on your needs.

Key Notes

a. The participant must be conversant with English.

b. Upon completion of training the participant will be issued with an Authorized Training Certificate

c. Course duration is flexible and the contents can be modified to fit any number of days.

d. The course fee includes facilitation training materials, 2 coffee breaks, buffet lunch and A Certificate upon successful completion of Training.

e. One-year post-training support Consultation and Coaching provided after the course.

f. Payment should be done at least a week before commence of the training, to DATASTAT CONSULTANCY LTD account, as indicated in the invoice so as to enable us prepare better for you.